Since their introduction in the 1940s, epoxies have been essential to a wide variety of industries and applications. Epoxy resin is an extremely durable material that is administered in liquid form and cures to a temperature-resistant, high-clarity solid. The strength of cured epoxy resin, coupled with its quick curing speed makes it ideal for protective coating and filler in a wide range of products, from electrical components to flooring. In this guide, we will discuss what epoxy resin is, the different types of epoxy material, and what epoxy is used for.

What Is Epoxy Resin?

Epoxy, also known as polyepoxide, is a polymer that is used to create scratch-resistant protective coatings, fillers, and adhesive products for a variety of applications. Epoxy resin is viscous when in liquid form, cures quickly, and adheres to a wide range of substrate materials, including wood, metal, glass, concrete, and stone. At its most basic, epoxy is composed of a liquid epoxy resin and a chemical hardener that cures the resin into hardened plastic. Once hardened, epoxy is extremely strong, dimensionally stable, and chemical-resistant.

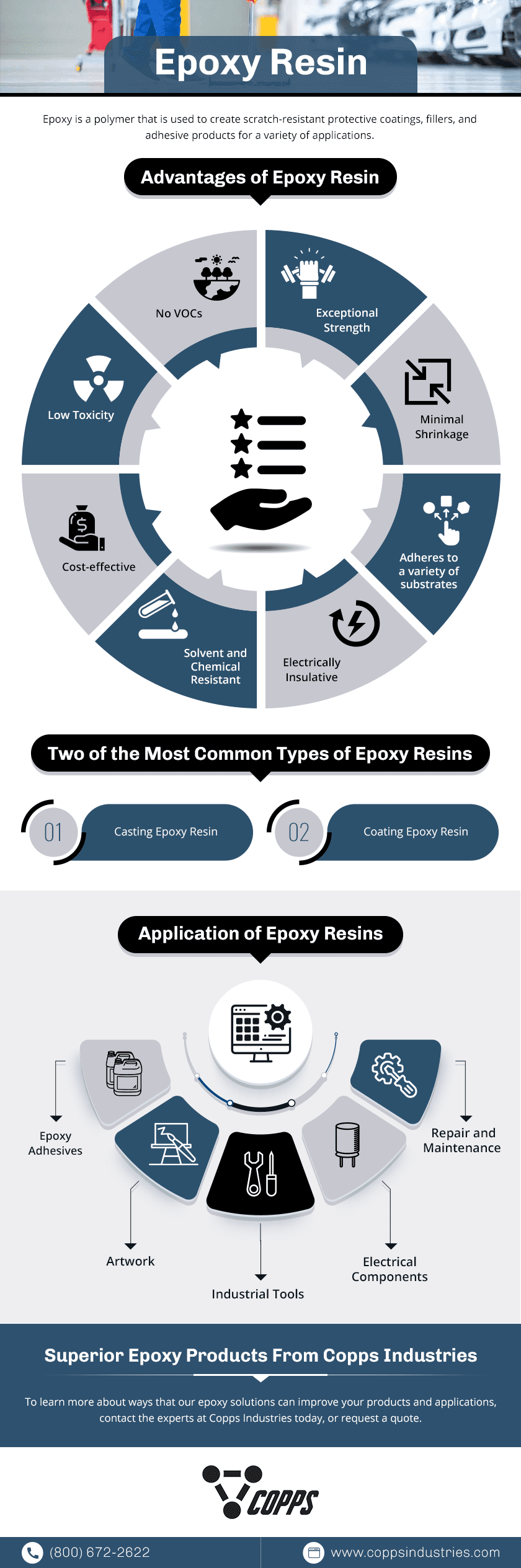

Epoxy offers a wide variety of advantages over other adhesives and coatings, including:

- Exceptional strength

- Minimal shrinkage

- Adheres to a variety of substrates

- Electrically insulative

- Solvent and chemical resistant

- Cost-effective

- Low toxicity

- No VOCs

How Strong Is Epoxy?

Epoxy materials are valued for their tensile strength and ability to bond firmly to a wide range of substrate materials. The bonding power and physical strength of epoxy differ widely depending on the resin blend and hardener used, as well as the material to which the epoxy is bonded. In general, the tensile strength of epoxy resins can range from 5,000 to 6,000 psi.

How to Use Epoxy Resin

Epoxy resin’s high bonding strength makes it difficult to remove from clothing, skin, and hair. In addition, the chemicals in epoxy resin can irritate your skin and lungs. It is therefore important to use adequate protective equipment, including nitrile gloves, a plastic apron, and safety goggles when handling epoxy for any project. Limit your exposure to epoxy fumes by applying epoxy in well-ventilated areas with open doors and windows.

If you happen to get epoxy resin on your skin or clothing, remove uncured material using isopropyl alcohol or acetone. Cured epoxy requires more attention but can be removed from surfaces with paint thinner or adhesive removers. Be careful with cured epoxy on your skin, as it can be more difficult to remove without injury. Vinegar and acetone nail polish remover can help to soften the material; however, if you are unable to remove it using these methods, seek assistance from a medical professional.

Different Types of Epoxy Resin

There is a wide range of epoxy resins available on the market, each with different formulations for a variety of substrates and uses. Two of the most common types of epoxy resins are casting epoxy resin and coating epoxy resin.

Casting Epoxy Resin

Casting epoxy resin, also known as pouring plastic or deep pour resin, is distinguished by its low viscosity and extended curing time. It is typically blended using a 2:1 ratio of liquid epoxy resin to hardener. The higher viscosity of this material makes it ideal for use in preservation applications in which an object is submerged within the epoxy. It can also be used to fill holes and gaps in materials to enhance their strength and stability.

Coating Epoxy Resin

Coating epoxy resin typically has a 1:1 mix ratio of resin to hardener and has a quicker curing time compared to casting epoxy resin. Coating epoxy resin is used to provide a strong, waterproof, chip-resistant, and rust-proof coating on items. Once cured, epoxy resin coatings are extremely durable, with an easy-to-clean, high-gloss surface.

Although casting and coating epoxies exhibit similar characteristics, it is important to select the epoxy resin that is best suited for the material and application.

Application of Epoxy Resins

The versatility, strength, and cost-effectiveness of epoxy resins make them the material of choice for a wide variety of industries and applications, including:

Epoxy Adhesives

As an adhesive, epoxy resin is a highly efficient and effective way to bond components made of wood, metal, plastic, glass, stone, and other materials for various applications. This makes them ideal for bonding aircraft and automotive components, recreational equipment such as skis and golf clubs, and other products that require a durable, waterproof bond that will withstand hard use.

Industrial Tools

Epoxy resins are often used to manufacture industrial tools such as injection and casting molds, laminates, prototype models, and component fixtures. As a replacement for more traditional metal and wood components, epoxy resin is more cost-effective because it is quicker and more efficient to manufacture.

Electrical Components

Epoxy resins are highly electrically insulative, which makes them ideal for enclosures and components in electrical systems, including motors, generators, printed wiring boards (PWBs), and transformers.

Repair and Maintenance

As one of the strongest adhesives on the market, epoxy resin is one of the most popular options for material repairs and maintenance. Since it cures rapidly and bonds to glass, ceramic, wood, concrete and metal, among other materials, it is a useful adhesive to keep on hand for day-to-day maintenance and even more complex repairs.

Artwork

Epoxy resins are frequently used by artists for a variety of artistic endeavors, including decorative furniture, pictures, and jewelry. The speed with which epoxy resin cures allows artists to quickly realize their artistic ideas and create enduring works that will stand the test of time.

Superior Epoxy Products From Copps Industries

Copps Industries is a leading provider of top-quality industrial epoxy for our customers in the mining and aggregate, civil and structural engineering, electrical, and electronics industries. Since 1979, we have been dedicated to finding superior epoxy solutions for even the most demanding and complex applications. To learn more about ways that our epoxy solutions can improve your products and applications, contact the experts at Copps Industries today, or request a quote.