Copps Industries manufactures a complete line of 100% solids, industrial concrete floor coatings and overlays. We provide solutions for your severe flooring environment.

Industrial Concrete Flooring

Our comprehensive line of 100% solids, VOC-free epoxy, industrial concrete floor coatings and overlays are innovative and cost effective. Our concrete floor coatings and resurfacers provide solutions for the most severe flooring and restoration needs, and have been successfully installed in chemical processing, power generation, tool and die, pulp and paper, food and beverage facilities worldwide.

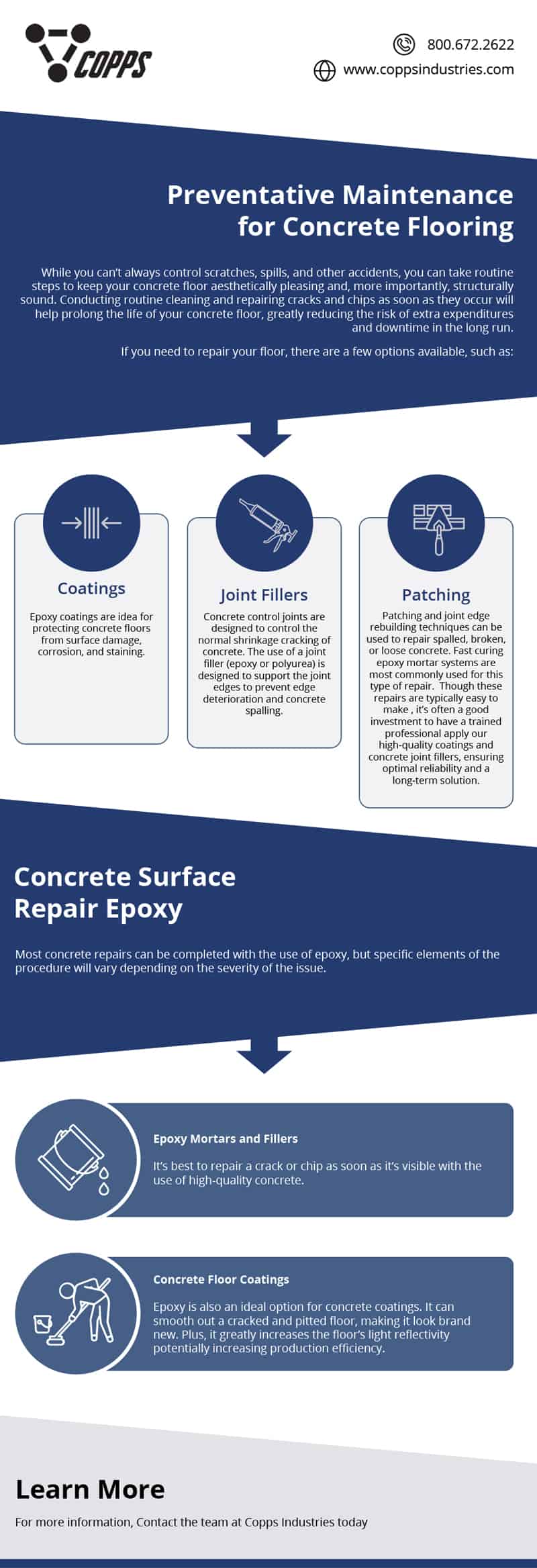

Preventative Maintenance For Concrete Flooring

While you can’t always control scratches, spills, and other accidents, you can take routine steps to keep your concrete floor aesthetically pleasing and, more importantly, structurally sound.Conducting routine cleaning and repairing cracks and chips as soon as they occur will help prolong the life of your concrete floor, greatly reducing the risk of extra expenditures and downtime in the long run.

If you need to repair your floor, there are a few options available, such as:- Coatings— Epoxy coatings are idea for protecting concrete floors from surface damage, corrosion, and staining.

- Joint Fillers – Concrete control joints are designed to control the normal shrinkage cracking of concrete. The use of a joint filler (epoxy or polyurea) is designed to support the joint edges to prevent edge deterioration and concrete spalling.

- Patching – Patching and joint edge rebuilding techniques can be used to repair spalled, broken, or loose concrete. Fast curing epoxy mortar systems are most commonly used for this type of repair. Though these repairs are typically easy to make , it’s often a good investment to have a trained professional apply our high-quality coatings and concrete joint fillers, ensuring optimal reliability and a long-term solution.

Concrete Surface Repair Epoxy

Most concrete repairs can be completed with the use of epoxy, but specific elements of the procedure will vary depending on the severity of the issue.

- Epoxy mortars and fillers — It’s best to repair a crack or chip as soon as it’s visible with the use of high-quality concrete.

- Concrete floor coatings — Epoxy is also an ideal option for concrete coatings. It can smooth out a cracked and pitted floor, making it look brand new. Plus, it greatly increases the floor’s light reflectivity potentially increasing production efficiency.

Learn More

For more information, Contact the team at Copps Industries today or download the technical specs below.

At Copps, our mission is a cleaner, healthier, more sustainable world.

| Product | Components | Working time

@22°C (72°F) minutes |

Initial cure

or foot traffic @22°C (72°F), hrs. |

Compressive Strength,

psi |

Hardness, Shore | Chemical Resistance

Rating |

Application | Safety Data Sheet (SDS) | Technical Specs |

|---|---|---|---|---|---|---|---|---|---|

| Armorgard 500 | 2 part pigmented | 25 | 9 | 12,500 | 85D | Very Good | Pigmented, 10-40mil, self leveling | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 501 | 2 part clear | 25 | 4 | 12,000 | 85D | Very Good | Low temp 40F, Organic Acid Resistance | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 502 | 3 part pigmented | 20 | 10 | 7,000 | 85D | Excellent | 98% Sulfuric Acid, 15mil coating | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 506 | 2 part clear | 25 | 8 | 9,500 | 82D | Very Good | Fast, low temp cure, 40F | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 507 | 2 part clear | 25 | 12 | 12,000 | 82D | Very Good | Clear, 10-40mil, self leveling | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 522 | 2 part Pigmented | 35 | NA | 12,500 | 91D | Good | Pigmented, Barrier Coating | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 524 | 2 part Pigmented | 20 | 8 | 10,100 | 88D | Excellent | Pigmented, High Chemical Resistance | Login to access the Safety Data Sheets (SDS) |

|

| General Purpose Epoxy 525 | 2 part clear and pigmented | 20 | 16 | 12,000 | 78D | Good | 10-20mil, self leveling | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 700UV | 2 part clear | 25 | 12 | 12,000 | 82D | Very Good | UV, Clear Topcoat for Color Quartz | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 700 | 2 part clear | 25 | 12 | 12,000 | 82D | Very Good | Clear, Color Quartz, self leveling | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 600T | 3 part natural or pigmented aggregate | 60 | 4 | 10,500 | 86 D | Excellent | 1/4 overlay, general purpose, heavy duty | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 601T | 3 part natural or pigmented aggregate | 60 | 4 | 12,000 | 87 D | Excellent | 1/4 overlay, organic acids, heavy duty | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 602T | 3 part natural or pigmented aggregate | 45 | 5 | 11,000 | 94D | Excellent | 1/4 overlay, 98% H2SO4 | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 604T | 3 part natural or pigmented aggregate | 10 | 1 | 12,800 | 92D | Excellent | 1/4 overlay, Low temp 20F Cure | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 600SF | 3 part natural or pigmented aggregate | 60 | 4 | 12,500 | 86D | Excellent | 1/8″ Slurry, general purpose | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 601SF | 3 part natural or pigmented aggregate | 60 | 4 | 12,300 | 87D | Excellent | 1/8″ Slurry, Acid Resistance | Login to access the Safety Data Sheets (SDS) |

|

| Epoxy Primer (K-049) | 2 part clear | 20 | 16 | NA | 78D | Moderate | General purpose primer | Login to access the Safety Data Sheets (SDS) |

|

| Epoxy Primer (K-040) | 2 part clear | 20 | 12 | NA | 85D | Moderate | Concrete Primer Fast Cure | Login to access the Safety Data Sheets (SDS) |

|

| FlexFill 60 Joint Filler (K-057) | 2 part pigmented | 60 | 16 | NA, elastomeric | 78A | Moderate | High elongation joint filler | Login to access the Safety Data Sheets (SDS) |

|

| Flexfill 80 Joint Filler (K-554) | 2 part pigmented | NA | 1 | NA, elastomeric | 80A | Moderate | High elongation joint filler | ||

| FlexFill 90 Joint Filler (K-560) | 2 part pigmented | 10 | 16 | NA, elastomeric | 92A | Moderate | Fast setting joint filler | Login to access the Safety Data Sheets (SDS) |

|

| Floor Patch (K-002) | 3 part gray aggregate | 45 | 4 | 7000 | 75D | Moderate | Concrete Floor Patching | Login to access the Safety Data Sheets (SDS) |

|

| Armorgard 295 | 3 part broadcast | 60 | 12 | 11,900 | 84D | Good | Broadcast, Vapor Retarder | Login to access the Safety Data Sheets (SDS) |

<!–

–>