Abrasion refers to the phenomenon of one surface rubbing or grinding away material from another. Incorporating wear resistance properties into industrial systems, parts, and products protects them against abrasive elements. By providing a protective barrier, wear-resistant products contribute to increased system lifespan, decreased overall maintenance costs, and consistent performance.

In an emergency, an application of abrasion-resistant epoxy may also extend the life of previously worn parts. This capability helps industrial operations keep equipment working until critical replacement parts arrive or a scheduled shutdown occurs.

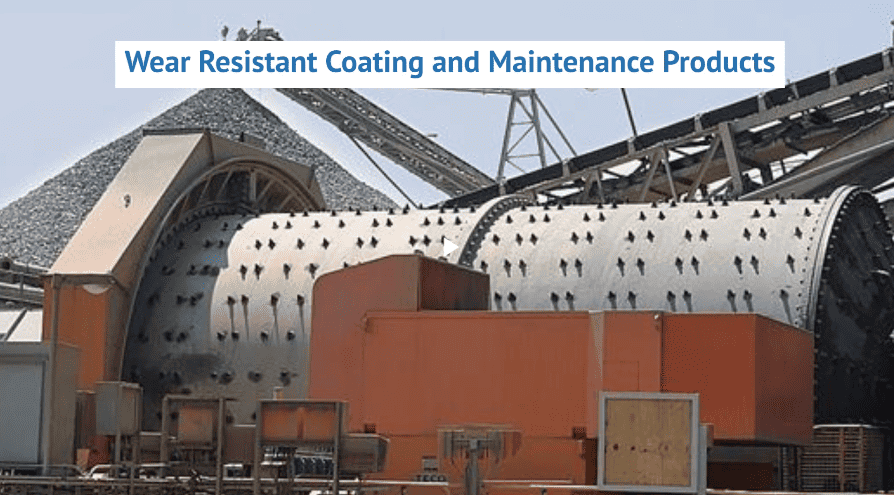

Our Wear Resistant Coating and Maintenance Products

Copps Industries provides a full range of maintenance and wear-resistant epoxy products to protect your systems from abrasion and deterioration over time. Our engineered Armor Plate line consists of alumina ceramic and steel-filled repair epoxies that feature easy application and excellent performance in a range of industrial equipment. Armor Plate products feature abrasion- and corrosion-resistant epoxy compounds designed to repair, rebuild, and extend the service life of a wide range of plant equipment in numerous industries, including mining, aggregate, power generation, and more.

Armor Plate product solutions will keep your equipment in top operating condition longer, decreasing unplanned downtime, and help users get equipment back into service in hours instead of days. With service temperatures up to 450°F (232°C) and documented chemical and corro

sion resistance, the Armor Plate line is a beneficial value-add for industries worldwide.

Enlisting high-performance epoxy repair products like Armor Plate ensures part effectiveness under a wide range of conditions. Whether your application requires overhead or vertical positioning, our epoxy products will never sag, collapse, or drip. We also offer a variety of media options to meet varying needs, including ceramic epoxy and metal epoxy.

Our Armor Plate products have been used to repair and reinforce:

- Pump casings

- Cyclones

- Pipe elbows

- Slurry lines

- Vibrating screens

- Castings

- Shafts and propellers

- Chutes

- Screw conveyors

These examples demonstrate how our ceramic and metal epoxy solutions can protect a broad range of mechanical equipment from abrasion and wear. Our diverse product line ensures that we can provide a custom epoxy repair solution that effectively mitigates abrasion damage in virtually any application.

Partnering With Copps Industries

Copps Industries has partnered with businesses of all sizes for decades to develop custom solutions for demanding industrial epoxy challenges. Whatever your unique situation, our time-tested products, years of experience, and expert team will deliver a solution that exceeds your expectations.

While numerous providers claim to produce effective wear materials, only a handful of established firms offer and support a practical portfolio of economical, uniquely formulated solutions that solve real-world problems. As an industry leader in custom formulations and private label manufacturing, Copps Industries supplies wear-resistant epoxy and epoxy repair products to numerous leading international OEMs.

When you partner with Copps Industries for your metal and ceramic epoxy needs, one thing becomes clear—you can spend more, but you can’t buy better! Our best-in-class epoxy repair products offer robust solutions for abrasion that will help your mechanical components reach their full lifespan and attain the best possible performance metrics. Contact us for more information about our product line, or request a quote today.

Wearing Compounds & Metal

Repair Products eBook

Compuestos Anti-desgaste y Reparadores de metales Full A-Z Guide For

Wear-Resistant Epoxy

| Product | Media Type | Appearance | Max. Service Temperature, F° | Pot life @ 22°C, min. | Curetime @ 22°C hrs. | Compressive Strength, psi | Hardness, Shore D | Safety Data Sheet (SDS) | Technical Specs |

|---|---|---|---|---|---|---|---|---|---|

| K-036 Ceramic Regular | Ceramic | Non Sag Paste | 350 | 60 | 12 | 17,000 | 85 | ||

| K-046 Ceramic Regular Non-Corrosive | Ceramic | Non Sag Paste | 350 | 60 | 12 | 16,000 | 85 | Login to access the Safety Data Sheets (SDS) |

|

| K-038 Ceramic Fast | Ceramic | Non Sag Paste | 250 | 30 | 3 | 16,500 | 90 | ||

| K-097 Ceramic Fast Large Bead | Ceramic | Non Sag Paste | 250 | 30 | 3 | 14000 | 90 | Login to access the Safety Data Sheets (SDS) |

|

| K-037 Ceramic High Temp | Ceramic | Non Sag Paste | 450 | 90 | 8+3 @ op.temp. | 16,000 | 90 | Login to access the Safety Data Sheets (SDS) |

|

| K-050 Ceramic Large Bead | Ceramic | Non Sag Paste | 250 | 30 | 7 | 12,500 | 90 | ||

| K-060 Armor Plate Ceramic | Ceramic | Non Sag Paste | 300 | 30 | 7 | 14,000 | 85 | ||

| K-015 Brushable Ceramic | Ceramic | Brushable Liquid | 200 | 30 | 6 | 11,000 | 87 | Login to access the Safety Data Sheets (SDS) |

|

| K-096 Brushable Ceramic | Ceramic | Brushable Liquid | 225 | 30 | 7 | 17,700 | 93 | Login to access the Safety Data Sheets (SDS) |

|

| K-054 CRC | Ceramic | Non Sag Paste | 200 | 15 | 5-7 | 14,500 | 85 | Login to access the Safety Data Sheets (SDS) |

|

| K-081 Steel Fast | Steel | Non Sag Paste | 250 | 15 | 3 | 15,000 | 90 | Login to access the Safety Data Sheets (SDS) |

|

| K-033 Steel Regular | Steel | Non Sag Paste | 250 | 40 | 8 | 12,000 | 90 | ||

| K-094 Steel Super Fast | Steel | Non Sag Paste | 200 | 3 | 1 | 86 | Login to access the Safety Data Sheets (SDS) |

||

| K-032 Steel Xtra Fast | Steel | Non Sag Paste | 125 | 5 | 1 | 8,200 | 84 | Login to access the Safety Data Sheets (SDS) |

|

| K-035 Steel Pourable | Steel | Viscous Liquid | 225 | 20 | 8-12 | 15,100 | 91 | ||

| K-064 Steel High Temp | Steel | Non Sag Paste | 450 | 90 | 8+3 @ op.temp. | 13,000 | 90 | Login to access the Safety Data Sheets (SDS) |

|

| K-931 Silicon Carbide | Silicon Carbide | Non Sag Paste | 200 | 30 | 7 | 14,000 | 90 | Login to access the Safety Data Sheets (SDS) |

|

| K-030 Titanium | Titanium | Non Sag Paste | 250 | 20 | 6 | 20,000 | 90 | Login to access the Safety Data Sheets (SDS) |

|

| K-042 Aluminum | Aluminum | Non Sag Paste | 250 | 40 | 8 | 14,000 | 86 | Login to access the Safety Data Sheets (SDS) |

|

| K-019 Aluminum | Aluminum | Non Sag Paste | 400 | 90 | 16 | 18,000 | 90 | ||

| K-053 Aluminum | Aluminum | Viscous Liquid | 450 | 60 | 16 | 18,000 | 90 | ||

| K-044 Graphite | Graphite | Non Sag Paste | 250 | 40 | 8 | 10,000 | 80 | Login to access the Safety Data Sheets (SDS) |

|

| K-003 Graphite | Graphite | Viscous Liquid | 350 | 30 | 12 | 9,000 | 85 | ||

| K-045 Graphite | Graphite | Viscous Liquid | 250 | 30 | 8 | 12,000 | 80 |

Download Our eBook

Copps Industries is an ISO 9001-2008 certified global formulator/supplier of industrial grade epoxy problem solvers. Our ever expanding product line includes precast form coating and repair materials, industrial concrete floor coatings and joint fillers, alumina ceramic wear resistant and steel filled repair epoxies, crusher and mill products, ”DOT” materials, adhesive, potting and encapsulation systems.

Learn More