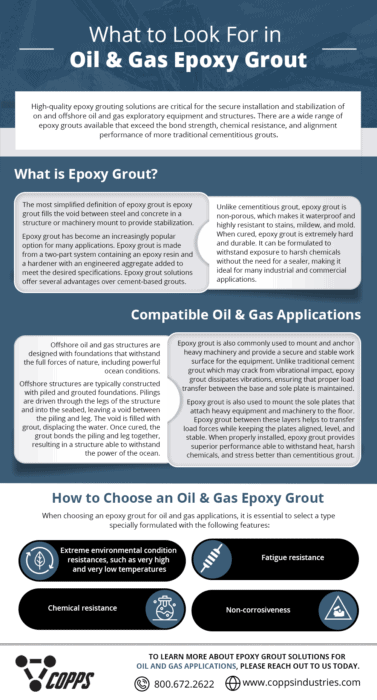

High-quality epoxy grouting solutions are critical for the secure installation and stabilization of on and offshore oil and gas exploratory equipment and structures. There are a wide range of epoxy grouts available that exceed the bond strength, chemical resistance, and alignment performance of more traditional cementitious grouts.

In this blog, we’ll cover the basics of epoxy grout, suitable applications, and selection considerations for the oil and gas industry.

What is Epoxy Grout?

The most simplified definition of epoxy grout is epoxy grout fills the void between steel and concrete in a structure or machinery mount to provide stabilization.

Epoxy grout has become an increasingly popular option for many applications. Epoxy grout is made from a two-part system containing an epoxy resin and a hardener with an engineered aggregate added to meet the desired specifications. Epoxy grout solutions offer several advantages over cement-based grouts.

Unlike cementitious grout, epoxy grout is non-porous, which makes it waterproof and highly resistant to stains, mildew, and mold. When cured, epoxy grout is extremely hard and durable. It can be formulated to withstand exposure to harsh chemicals without the need for a sealer, making it ideal for many industrial and commercial applications.

Compatible Oil & Gas Applications

Offshore oil and gas structures are designed with foundations that withstand the full forces of nature, including powerful ocean conditions.

Offshore structures are typically constructed with piled and grouted foundations. Pilings are driven through the legs of the structure and into the seabed, leaving a void between the piling and leg. The void is filled with grout, displacing the water. Once cured, the grout bonds the piling and leg together, resulting in a structure able to withstand the power of the ocean. The characteristics of epoxy grout make it an ideal choice for offshore applications.

Epoxy grout is also commonly used to mount and anchor heavy machinery and provide a secure and stable work surface for the equipment. Unlike traditional cement grout which may crack from vibrational impact, epoxy grout dissipates vibrations, ensuring that proper load transfer between the base and sole plate is maintained

Epoxy grout is also used to mount the sole plates that attach heavy equipment and machinery to the floor. Epoxy grout between these layers helps to transfer load forces while keeping the plates aligned, level, and stable. When properly installed, epoxy grout provides superior performance able to withstand heat, harsh chemicals, and stress better than cementitious grout.

Download Our eBook

Epoxy grouts are able to meet the stringent structural demands of onshore and offshore oil & gas equipment by providing superior bond strength, alignment performance, and chemical resistance relative to traditional cementitious grouts. Our eBook, A Complete Guide to Oil and Gas Epoxy Grouting Solutions, provides a comprehensive overview of epoxy grouts for oil & gas applications.

How to Choose an Oil & Gas Epoxy Grout

When choosing an epoxy grout for oil and gas applications, it is essential to select a type specially formulated with the following features:

- Extreme environmental condition resistances, such as very high and very low temperatures

- Fatigue resistance

- Chemical resistance

- Non-corrosiveness

Epoxy grout with these features will ensure long-lasting security, stability, and alignment.

At Copps Industries, we have several epoxy grout solutions formulated for common conditions encountered in oil and gas applications. For example:

- X-TRA Temp High Performance Grout (K-052) is formulated for extreme high-temperature applications that require chemical resistance and durability. X-TRA Temp High Performance Grout has a service temperature of as high as 425° F with a very low mixed viscosity of 7,000 cP.

- Low Temperature (K-026) is designed for cold weather applications, and allows for pouring in air temperatures between 25° F and 60° F, with a mixed viscosity of 20,000 cP at 40° F. Low Temperature (K-026) is an ideal grout for use in cold climates where outdoor pours are required.

An experienced manufacturer and distributor can assist you in selecting the most appropriate epoxy grout solution for your specific application. When sourcing epoxy grout for your project, ensure that you choose a provider who has an ISO 9001:2015 certification. Adherence to this standard ensures a product that was created under strict quality assurance procedures.

Oil & Gas Epoxy Grout Solutions at Copps Industries

At Copps Industries, we are committed to providing our clients with unparalleled service and the highest quality products available. We are an ISO 9001:2015 certified manufacturer and supplier of industrial-grade epoxy, offering a wide range of unique and proven formulated systems. We have been using innovative practices and cutting-edge technology to develop solutions that address complex challenges within a variety of industries since 1979.

To learn more about epoxy grout solutions for oil and gas applications, please reach out to us today.

Tags: epoxy grout

Request Quote

Request Quote